CNC is the abbreviation of Computer Numerical Control, which means “computer data control”. A kind of NC machining is an advanced processing technology in today’s mechanical manufacturing. Firstly, if you want to know more the stories or projects of CNC machining, you can visit waykenrm.com.

It is an automatic processing method with high efficiency, high precision and high flexibility. It is to input the NC program of the workpiece to the machine tool, under the control of these data, the machine tool automatically processes the workpiece that meets people’s wishes to produce wonderful products, so that the artist’s imagination can be turned into a real commodity. NC machining technology can effectively solve such complex, precise and small batch of changeable processing problems as dies, fully adapted to the needs of modern production. CNC machining is fast for low volume metal parts, normally under 500, however if you need 100,000 parts ,then injection molding is the way to go. check qmolding for more information

1. The features of CNC machining parts

1.1 High precision & High efficiency

High precision and high efficiency are the eternal theme of CNC machining. Generally speaking, the fixed abrasive processing continuously pursues the processing accuracy of free abrasive, while the free abrasive processing continuously pursues the efficiency of fixed abrasive processing. Current ultra-precision addition technologies such as CMP and EEM can achieve very high surface quality and integrity, but at the expense of processing efficiency. Although ultra-precision cutting and grinding technology has high processing efficiency, it can’t obtain processing accuracy such as CMP and EEM. Exploring processing methods of efficiency and accuracy have become the goal of researchers in the field of ultra-precision machining. The appearance of Semi-fixed abrasive processing method reflects this trend. On the other hand, electrolytic magnetic abrasive finishing (EMF) and magnetorheological abrasive flow machining (MRF) were developed Rapid Direct.

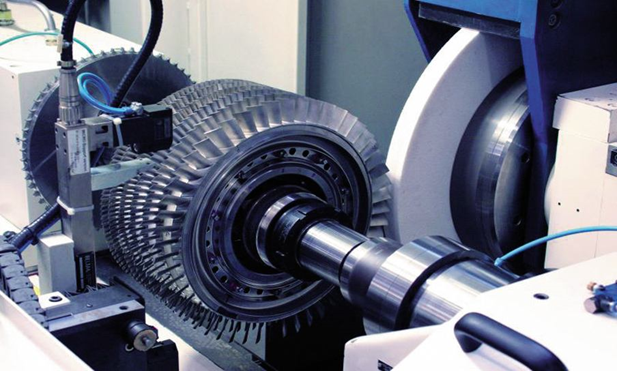

Figure 1: High precision parts

1.2 Process Integration

Nowadays, competition among enterprises tends to be white-hot, and high production efficiency is increasingly becoming the condition for enterprises to survive. In this context, the voice of “grinding instead of grinding” or even “grinding instead of throwing” appeared. On the other hand, the trend of using one equipment to complete a variety of processing (such as turning, drilling, milling, grinding, finishing) is becoming more and more obvious.

1.3 Upsizing & microminiaturization

With the development of national defense, aviation, aerospace industry, it needs the support of large-scale and good performance CNC machine tools. Ultra-precision machining technology and micro-nano technology can be one of strategic technologies in the 21st century. Also, new manufacturing technologies and equipment that can adapt to micro-size and micro-nano processing accuracy need to be developed.

2. The application of CNC machining

CNC machining are mainly suitable for workpieces with complex shape, many processes and high precision requirements. Such as, Complex Surface Parts, Special-shaped parts, Parts in the trial production of new products, and so on.

2.1 Complex Surface parts

In the industry design, aviation and transportation industry, parts with complex curved surface are widely used, such as cam, integral impeller of aviation, propeller, die cavity, etc. This kind of parts with complex curves and curved surface outlines, or with an open inner cavity of -box or shell parts, can’t achieve the desired processing accuracy by ordinary machine tools or precision casting, and it is difficult to detect. The use of multi-axis CNC machining , combined with automatic programming technology and special cutting tools, can greatly improve its production efficiency and ensure the shape accuracy of the surface, making the automatic processing of complex parts very easy.

Figure 2: Complex Surface parts

2.2 Special-shaped parts

Special-shaped parts are irregular parts, which mostly need multi-station mixed processing of points, lines and surfaces (such as bracket, base, die relief, etc.). When processing special-shaped parts, the more complex the shape is and the higher the precision requirement is, the better the CNC machining can show its superiority.

2.3 Complex structure parts

They are widely used in industrial robot, automobiles, aircraft and other industries, such as gear pump shell, clamping device for industrial robots etc. In the CNC machining, 60%-95% of the process content of the ordinary machine tool can be completed by one clamp. In addition, depending on the characteristics of the CNC machining itself, such as high accuracy, high processing efficiency, good stiffness and automatic tool change, as long as the process flow is worked out well and the reasonable special fixture and tool are adopted, the precision of box parts can be solved. Higher degree requirement, more complex process and improve production efficiency and other issues.

Figure 3: Complex structure parts

2.4 Parts in the trial production of new products

CNC machining has a wide range of adaptability and high flexibility. When changing the processing object, only compiling and inputting new programs can realize the processing. Sometimes it can also be processed by modifying parts of the program or by using some special instructions. For example, parts with the same shape but different sizes can be processed by using the scaling function instruction, which provides great convenience for single piece, small batch and multi-variety production, product modification and trial production of new products, and greatly shortens the production preparation and trial production cycle.

Figure 4: the trial production of new products

3. The development of CNC machined parts

In recent years, product functions have multiplied, core components have been miniaturized, and peripheral accessories have been shrinking synchronously, making the body of scientific and technological products increasingly thin and small. Therefore, miniaturization, refinement and miniaturization of components are inevitable manufacturing trends.

Figure 5: Morden CNC machined parts

Under the intensification of competition in the digital era, in order to meet the trend of high demand for terminal consumer products, product are being developed from the old to the new, demand for small batches of customization, demand for product portability, the surge of mobile communication products, and the widespread use of medical and biomedical related products for the benefit of human health, all of which make the development of CNC machined part toward “light, thin, short and small”. With the development trend of “multi-function, fast, high-energy and low-cost”, miniaturization and customization technology will become the focus of development in the coming future.

Add Comment